In conveying systems, we often hear about problems with ‘stalled conveyors’, so in this article, we would like to offer a couple of solutions to avoid trouble with stalled conveyors, or even avoid stalling.

There are 3 key elements in conveying systems, which are...

For conveying systems, the importance of speed stability is almost self-explanatory. If the component does not arrive within the expected time, it will directly affect the productivity, or even worse, it can result in failures in production. The Brushless Motors from Oriental Motor are fitted with a hall IC on the rear of the motor, and makes a closed loop control system.

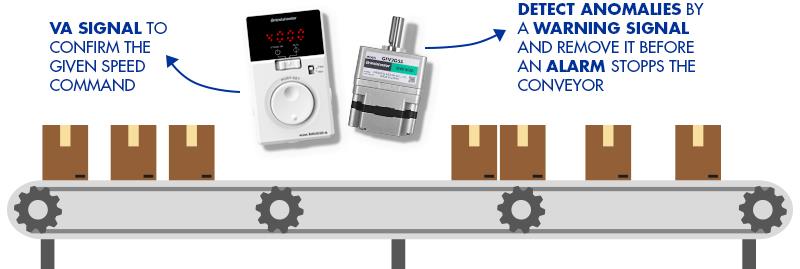

For BMU series, which is an entry model for conveying systems, the speed stability is ±0.5%. Also, there is a ‘VA’ signal which is very convenient to confirm that the motor is turning at the given command speed. The conventional method to confirm the speed is to compare the command speed (e.g. Analogue voltage), and the feedback (e.g. Count the pulses from the hall IC).

However, a counter was needed on the PLC as well as some programming. VA signal is a signal that is output when the actual speed is within a certain range of the command speed, and the range can be changed. Just check if the VA signal is ON or OFF, and you can see if the conveyor is moving at the desired speed.

Another feature of the BMU series is that you can set a certain load factor, and if the motor torque exceeds this level, the driver gives a warning and/or an alarm signal. With the warning, the motor continues to move, and with an alarm, the motor stops immediately. It is possible to set up different torque levels for the warning and alarm, so one way to use these signals is to detect anomalies by the warning signal and remove this anomaly (e.g. Too many components on the conveyor) before the conveyor stops with an alarm.

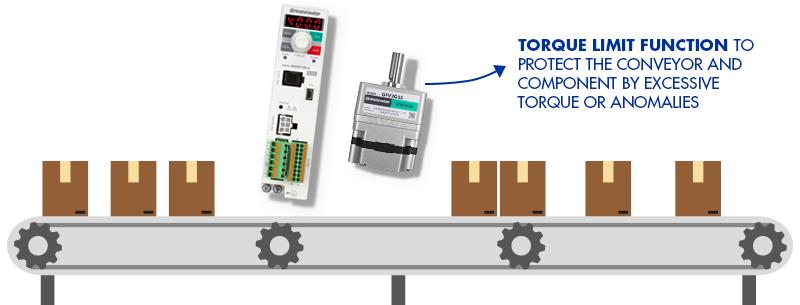

For Additional Features = Advanced Series BLE2

When further features are needed, we have an advanced series called BLE2. This driver has the features that BMU has, and additionally, it has a torque limit function. With BMU, you can detect if the motor torque exceeds a certain level, but you cannot limit the torque. With BLE2 series, you can set up a desired torque level to prevent the components on the conveyor or the conveyor itself from being damaged by excessive torque or anomalies.