Dynamic, textural, and symbolic; whether they ambitiously defy gravity or grow organically from the landscape, iconic buildings frequently involve complex façades. Designed not only to protect, they also regulate variables such as thermal and visual comfort.

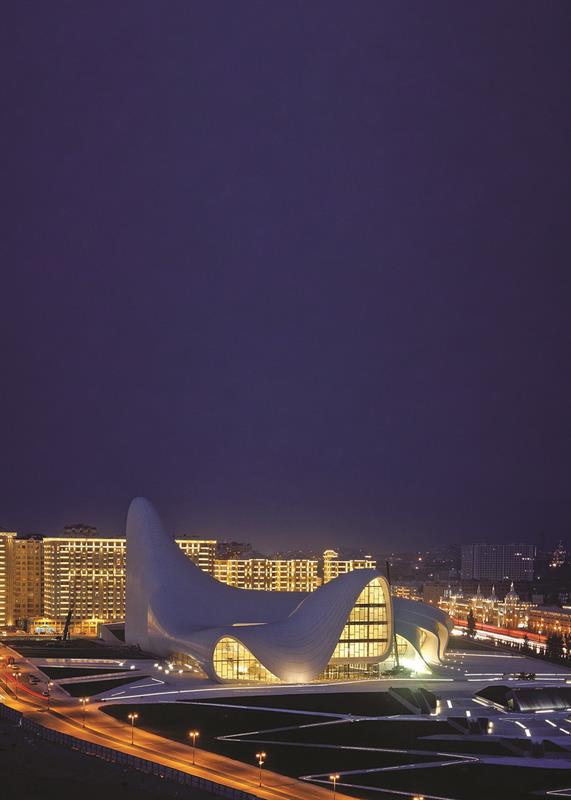

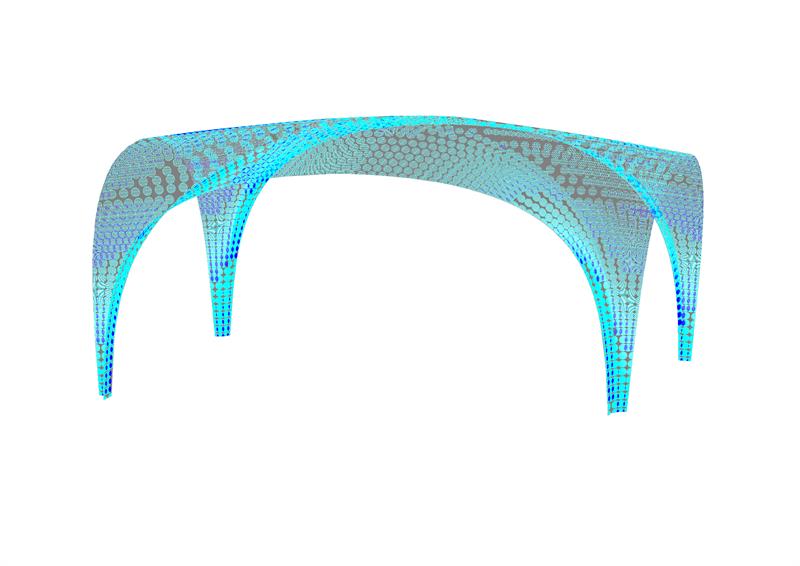

A specialist in this area, Newtecnic designs and analyses façade systems for use in high-profile public projects and regularly works with Zaha Hadid Architects, a practice recognised for its bold and fluid architectural forms. Newtecnic’s founders and current directors, Andrew Watts and Yasmin Watts, are known for their work on prominent projects including the iconic Federation Square (Melbourne, Australia) and more recently, the Heydar Aliyev Cultural Centre in Baku, Azerbaijan (see Figure 1).

Figure 1. Heydar Aliyev Cultural Centre, Baku, Azerbaijan.

Bespoke is the norm for Newtecnic, and every project requires thinking that goes far beyond conceptual design alone. Architects provide an artistic view and perhaps some surface modelling of a building design, then Newtecnic engineers build up the façade in layers, making sure that the design retains its creativity while also ensuring its structural integrity.

“Our clients want viable and economic design solutions that meet the required performance targets, can withstand environmental effects, and are easy to maintain,” says Carmelo Galante, head of Research and Development at Newtecnic. “A key aspect of our work is therefore to describe the physical behaviour of the façade systems we design.”

From solar studies that allow optimisation of the shading design in order to reduce cooling loads and maximise visual comfort, to the way in which fixing brackets for rainscreen cladding affect the integrity of the insulation, there are numerous challenges that can be resolved with the help of simulation.

Beyond Conceptual Design with Simulation

The COMSOL Multiphysics software has become a key tool for Newtecnic. Galante explains: “We can do everything within one simulation software. I use COMSOL to study the 3D thermal bridging effect—the way in which highly conductive materials penetrate insulation—on the overall energy efficiency of the build-up, evaluate the maximum temperature of components, and suggest the most suitable product or material. I can evaluate cladding pressures on the building structure for schematic design stages and study more complex façades in which mechanical and natural ventilation are present at the same time. I can also evaluate how different design configurations would affect the hygrothermal performance of a façade system.”

Using the CAD import functionality available in the COMSOL software, Galante often imports complex geometries, mainly from Autodesk AutoCAD software and Rhinoceros software. The use of Autodesk Revit software is continuously increasing at Newtecnic, and he considers the new LiveLink for Revit, an add-on to COMSOL that allows users to interface their simulations with the Revit environment, to be a powerful asset. Galante also combines the use of COMSOL with parametric design tools such as the programming language Grasshopper, which is used to build and analyse complex geometries by means of generative algorithms.

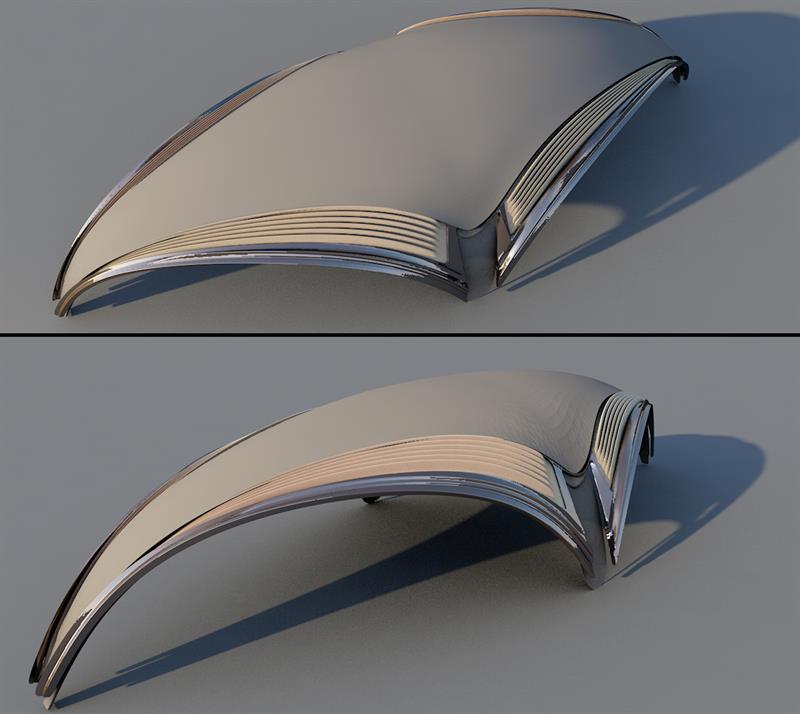

One current project at Newtecnic involves designing the façade system for a high-profile private building comprising a series of self-supporting concrete shells ranging from 10 to 80m in length and reaching heights of up to 30m (see Figure 2).

Figure 2. Rendering of a single shell shown from two different angles, many of which will be part of the building.

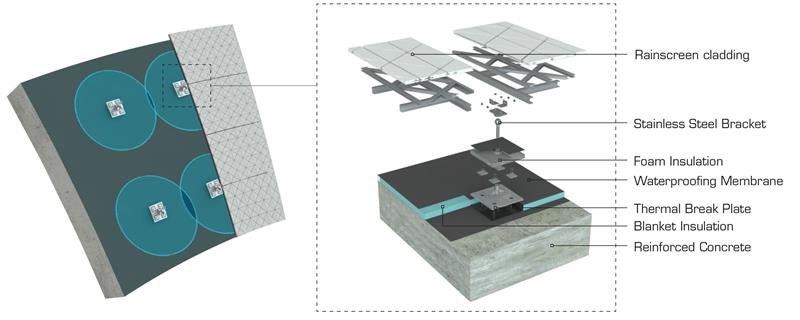

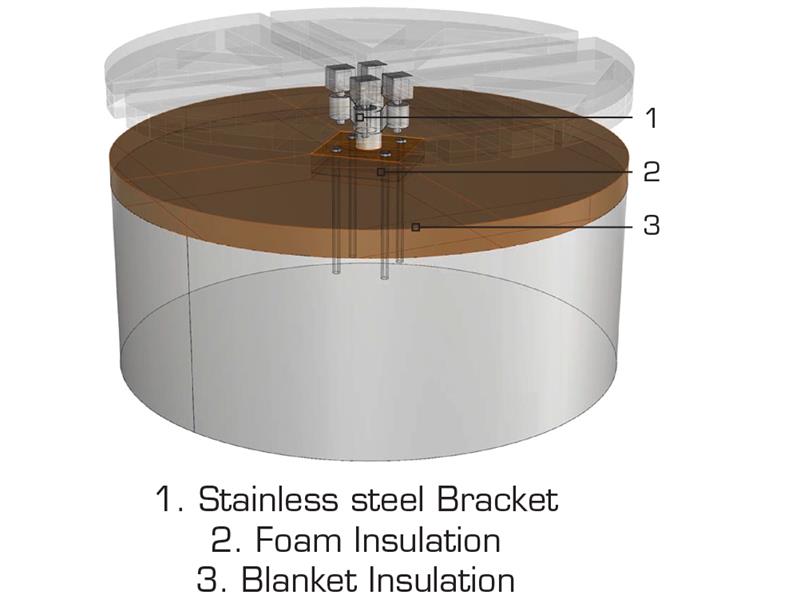

The concrete shells are clad with a rainscreen façade system made out of ceramic panels that are doubly curved in order to accurately reproduce the building geometry. Each panel is supported at its corners by adjustable fixing brackets made out of stainless steel. These brackets are attached to the concrete structure through four post-drilled anchorages, as shown in Figure 3. As the brackets penetrate the insulation layer and have a much higher thermal conductivity than the concrete structure, they create thermal bridges through the façade envelope, significantly reducing its thermal performance.

Figure 3. Highlighted view of the rainscreen system with fixing brackets.

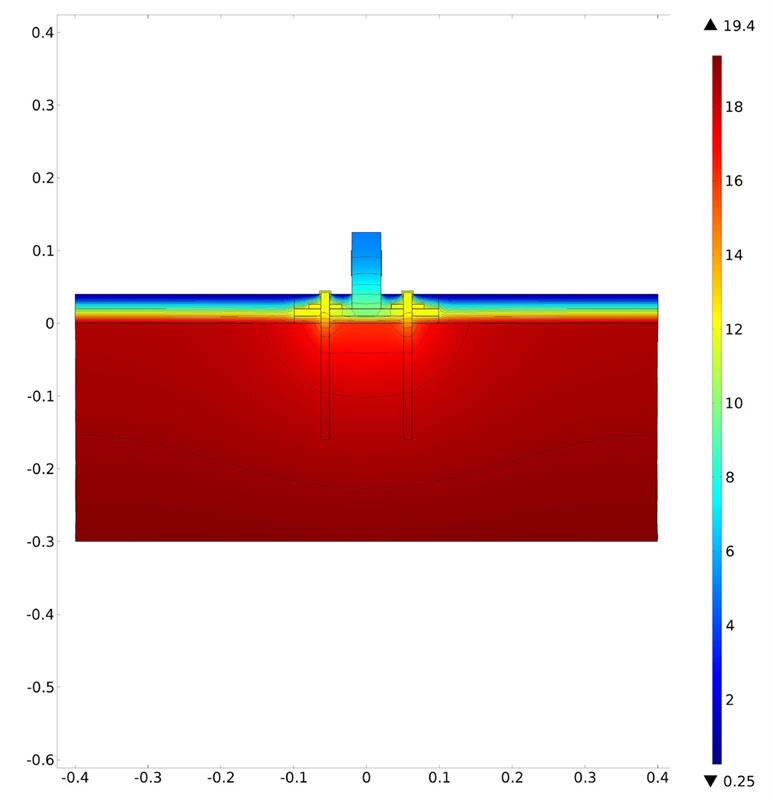

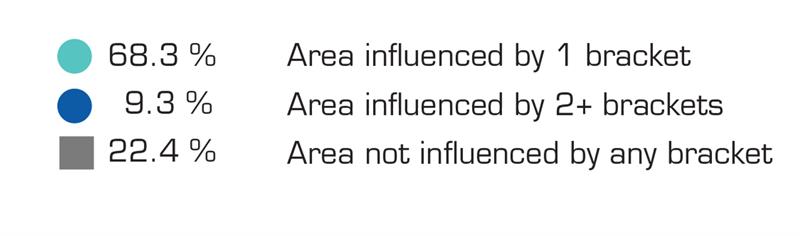

By conducting a simplified 2D study in COMSOL, Galante studied how the thermal bridge effect created by the brackets influenced the temperature distribution in the façade (see Figure 4). The results from the simulation were entered into a Grasshopper script to evaluate three areas of interest: those influenced by one bracket, those influenced by two or more brackets, and those not influenced at all (these areas are shown in Figure 5).

Figure 4. Simulation results showing isotherms and temperature profile in oC of a section taken through a bracket.

Figure 5. Model of one of the shells shown in Figure 2 with areas highlighted that are influenced by one bracket, two brackets, or not influenced by any bracket.

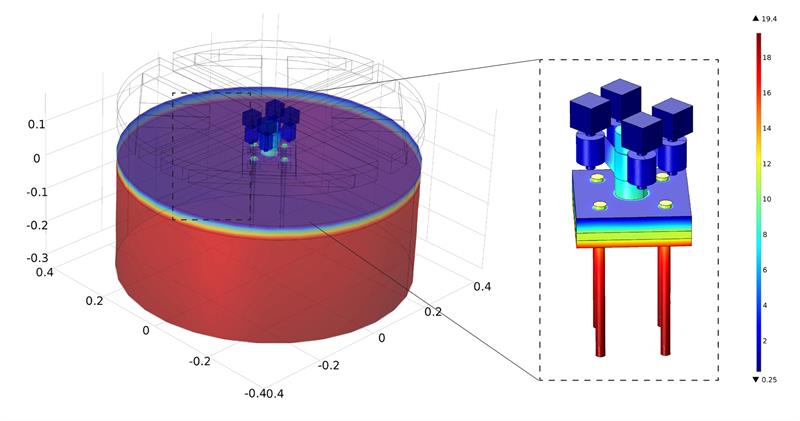

Galante was then able to prepare an accurate geometry for the system, including all the components of the build-up. “It is a real advantage to be able to combine two tools,” says Galante. “Grasshopper allows me to investigate the geometry on a very large scale—that of the entire building—then I move back to COMSOL with this information and create a very detailed 3D model to capture the real physics of the system.” Using this approach, Galante was able to conduct a 3D analysis to study the thermal bridge effect in the bracket and surrounding building (see Figure 6) and compute the global heat transfer coefficient (U-value) of the façade.

Figure 6. Left: 3D model of the brackets and surrounding insulation built in Rhinoceros software and imported into the COMSOL Multiphysics software. Centre: COMSOL software model showing the temperature profile in oC in the area influenced by the bracket. Right: Stainless steel bracket.

“Using multiphysics simulation allows me to develop a better understanding of the real situation,” explains Galante. “I can combine fluid flow with heat transfer by conduction, convection, and radiation, meaning that I can thoroughly evaluate the interplay of different physical effects and confirm the performance of different structures and materials.”

Responding to Design Changes

Newtecnic’s engineers have to respond to continually changing designs, and need to be able to validate any design updates. “Simulation allows us to do that,” observes Galante. “We can demonstrate exactly what effect a design change will have, whether it relates, for example, to energy efficiency, structural performance, corrosion, or the lifecycle of a component.”

For Newtecnic director Andrew Watts, it is all about answering questions such as “Is it worth changing this to make something else work?” or “If we have to change it, how much do we have to change it by?” He comments: “With simulation, we can move away from the traditional building philosophy of studying individual components that only perform one function and can instead think in terms of multi-functional components, and of the building as a whole.”

Simulation is used to conduct analyses for every component of a building, and these results are fully integrated with drawings so that budget estimates are both clear and comprehensive. Fabio Micoli, Associate Director at Newtecnic, notes the value of delivering live feedback to clients.

“Simulation minimises construction costs by allowing contractors to see exactly what they are required to build, thereby reducing the need for contingency budgets or time for unresolved design issues and allowing the construction team to concentrate on meeting project deadlines.”

Continuing Improvement

“The digital tools that we use, such as simulation software, enable us to explore new possibilities and improve our design processes,” Galante says. He and his colleagues can see potential for expanding the use of simulation at Newtecnic, including using the new Application Builder, now part of the COMSOL Multiphysics version 5.0. As Micoli notes, “We could, for example, enhance communication with clients by creating an application that allows an architect to modify different parameters and see exactly how changes would affect their design without knowing the underlying multiphysics simulation details.”

The bottom line is that with simulation, a better understanding of building performance can be delivered to Newtecnic’s clients than ever before, ensuring that an innovative architectural design puts its best face forward.

Carmelo Galante (left), Andrew Watts (middle), and Fabio Micoli (right) discuss a recent project at the Newtecnic office in London, UK.