Look at any industry today, from automotive design to consumer electronics, and you will find a common thread that binds them together: the demand for more innovative technology. The latest and greatest technologies are continuously surpassed by even more complex and intricate devices that offer advanced features and functionality.

Numerical simulation tools are a viable solution to the challenge of creating more elaborate devices quickly, delivering results with real-world accuracy without the need for building prototypes for each design modification.Some organisations, however, may not have the resources to bring a simulation expert on board to help create and modify models. This is where simulation applications come in. These customised user interfaces are built around numerical simulations of physics-based systems and allow an end user to run multiphysics analyses set up for them by simulation specialists.

With over 30 years of modelling experience in the industrial sector, Edward Furlani, a professor in the School of Engineering and Applied Sciences at University at Buffalo (UB) SUNY with joint appointments in the Departments of Chemical and Biological Engineering and Electrical Engineering, saw an opportunity to bring numerical simulation to a greater number of organisations. His idea: Organise a university group that could work together to develop mathematical models to analyse and design materials and devices for industrial purposes. Now, the potential for the team to extend the reach of their expertise to a broader range of industries is growing, thanks to the ability to create customised simulation apps using COMSOL Multiphysics software.

Bringing modelling expertise to many industries

For prof Furlani, multiphysics modelling has always been an important element in day-to-day work. As a research scientist at Eastman Kodak, he performed modelling in support of material and device development for commercial products, including inkjet systems and myriad digital imaging technologies. Prof Furlani also developed models for a range of industry needs, from photonics and microfluidics to applied magnetics and microsystems technology. In his current role as a professor at UB, Prof Furlani incorporates multiphysics software into the classroom to further help students learn and develop their engineering skills in an interactive way using computational tools.

The focus of Prof Furlani’s group at UB is highly interdisciplinary and reflects industrial and academic research.His graduate students develop multiphysics computational models for the development of products with functionality engineered all the way from the nanoscale to the macroscale. His group has created a number of COMSOL software models with the goal of helping industries continue on the path of innovation and growth.

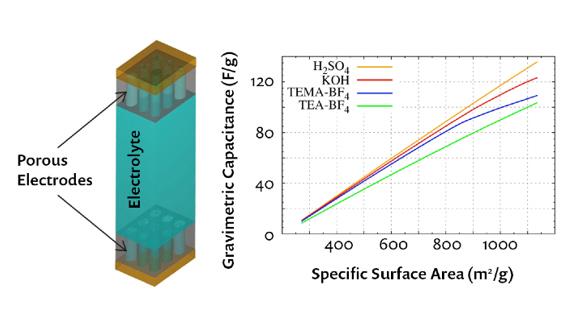

When it comes to energy storage, for example, electrochemical-based devices like electric double-layer capacitors (EDLCs) are becoming more and more common. Favoured over traditional capacitors for their significantly greater capacitance, these devices offer potential for new operating scenarios that require several rapid charge/discharge cycles. In the capacitors, ions separate and accumulate on the surface of the oppositely charged electrodes in response to an applied voltage. By developing models, Prof Furlani’s group, in collaboration with Professor Gang Wu at UB, has been able to predict ion transport and equilibrium charge accumulation within the devices, as well as their capacitance, to foster a better understanding of their behaviour and how to optimise their designs (see Figure 1).

Figure 1 The geometry of an EDLC and a plot indicating the predicted capacitance.

Membrane technology is another popular point of interest in the industrial community, with uses ranging from seawater desalination to CO2 removal from natural gas. Designing thin-film composite (TFC) membranes with high selectivity is the key to extending the use of membrane systems, keeping costs and the overall footprint at a minimum. The team at UB developed 3D models to see how layer thickness, selectivity, and porosity impact membrane performance. The models, which have been validated experimentally by Professor Haiqing Lin at UB, provide greater insight into how to further optimise these energy-efficient systems and pave the way for additional uses.

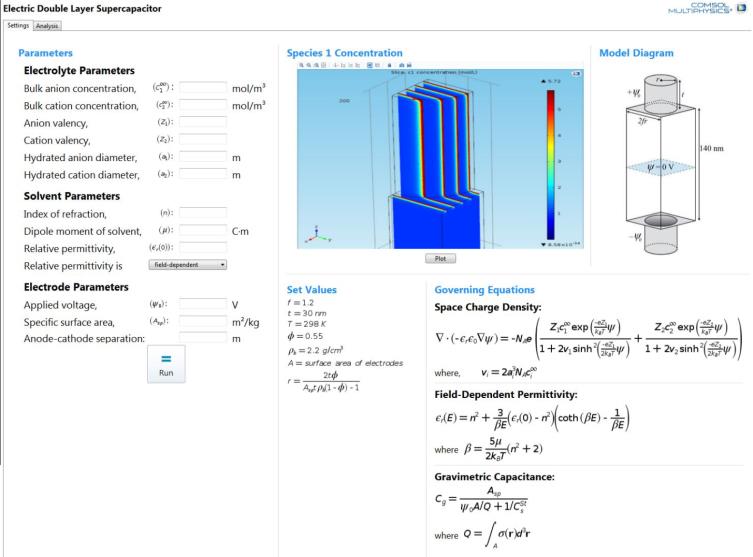

Figure 2 Cropped screenshot of an app for EDLC analysis.

Prof Furlani began turning these and other complex models into easy-to-use apps, as shown in Figure 2. Using the Application Builder available in COMSOL Multiphysics, he and his students were able to build a simplified interface on top of each model, customised to meet the specific needs of different companies, and empower a larger group of people to run their own simulation tests. "With custom applications, you have all of the power of COMSOL Multiphysics at your disposal without needing the expertise required to develop the underlying model," Prof Furlani said. "Users can study details that are difficult to measure and can greatly expedite their product development life cycle by reducing costly and time-consuming trial-and-error engineering."

To further promote economic development via mathematical modelling, the team is running COMSOL Server product on a computing cluster through the university's Center for Computational Research (CCR) — a supercomputing facility that supports scientific computing, software engineering, and parallel computing. This setup creates a high-performance and high-throughput computing environment for running apps where end users can connect to COMSOL Server through a client or a web browser. Behind-the-scenes simulation specialists can easily manage and deploy their apps and make any updates available right away through COMSOL Server.

The business of building customised simulation apps

The group has also been involved in simulation activities for the startup world. At Vader Systems, a startup company in Buffalo, NY, founders Zachary and Scott Vader have developed an innovative process known as liquid metal jet printing (LMJP). Designed to mimic inkjet printing, this technology, which is based on magnetohydrodynamics (MHD), involves liquefying a solid metal feed and ejecting molten metal droplets via a pulsed electromagnetic field. This enables the printing of highly complex 3D metal objects. As they commercialise printers based on LMJP, Prof Furlani’s group has developed COMSOL apps to better understand the printing process and enhance its capabilities.

Another important project has been carried out with scientists at Xerox led by Dr Peter Paul, where they contributed to the development of novel inductive loop sensing systems that can be used in vehicle transportation projects. Along with monitoring and managing traffic control, the remote sensing technology could also prompt new techniques for collecting traffic data.

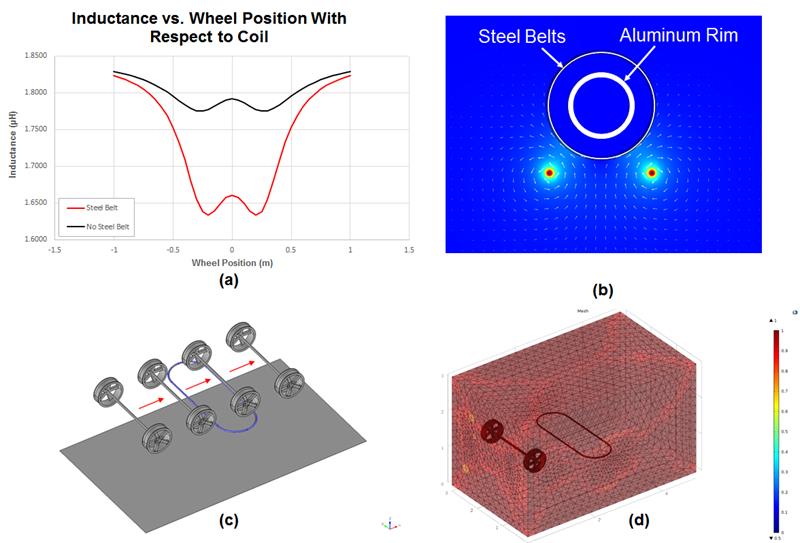

Maximising the performance of the systems requires an understanding of the electromagnetic coupling between the sensing coils that are embedded in the pavement and ferrous and metallic components of the vehicle, such as wheels and axles. Here the team used COMSOL Multiphysics to perform simulation studies to see how the coil inductance changes as a function of the position and motion of aluminium wheels and tires that contain steel belts (see Figure 3).

Figure 3: A simulation of an inductive coil coupling in a moving vehicle. The analysis examines the impact of steel belts in a moving tire on coil inductance (a) and the magnetic field distribution with a tire moving above an inductive coil (b). The vehicle axle motion is shown (c), as well as a 3D computational domain for simulating the detection of the axle (d).

While working on these and other projects, the need to involve more people in the design workflow for each of the projects became evident very quickly. With the underlying models established, the team sought to create an interactive tool that could include more people while meeting their individual needs. The answer came, once again, in the form of building custom applications.

"With simulation apps, you can easily customise the user interface and include parameters that are of interest to different companies, which is a very useful feature,” Prof Furlani stated.

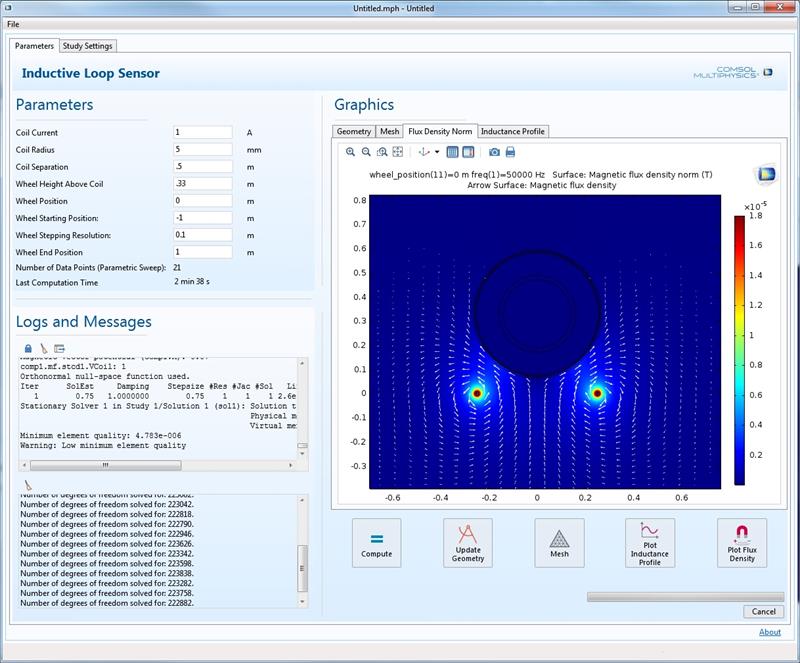

Such customisation and flexibility is complemented by the new ease of communicating to and throughout organisations. The need for an end user to use COMSOL Multiphysics is essentially eliminated through the installation of COMSOL Server, which provides access to apps. By bringing simulation capabilities into the hands of more people within the organisation, design changes can be addressed more efficiently with ensured accuracy. The teams at Vader Systems and Xerox (whose app is shown in Figure 4) have already experienced the benefits of using apps, such as creating a more collaborative and efficient product development cycle.

Figure 4: A screenshot of the app created for Xerox based on the underlying model for inductive loop sensing.

From students to entrepreneurs

Simulation tools are also an engaging way to help students enhance their engineering skills. Because apps are designed to hide the complexity of the underlying model, they can serve as a helpful guide to students who are newer to simulation or the COMSOL software. As they become more acquainted with the different features and functionality, students can begin to delve deeper and learn how to utilise new tools.

Aside from serving as a helpful introduction to the software, students have the opportunity to engage with the business side of creating apps. Designing an app, Prof Furlani notes, is not a one-step process. "There is also the work that goes into maintaining it," he said. "It is important that you stand by and provide support to customers, offering them help and engaging with them as they need it."

In this sense, the art and science of building apps develops business skills as students learn how to address questions and requests from customers in a timely manner. And by building apps on their own, students are adjusting to a new wave of simulation-led design, one that opens the door to greater freedom, flexibility, and entrepreneurship.