Sintering is the process of applying heat and/or pressure to fuse bits of metal, ceramic, and other materials into a solid mass. It’s nothing new. Nature has been fusing sedimentary minerals into slate and quartzite for eons, and humans began using similar methods to make bricks and porcelain millennia ago. Today, sintering is used to produce everything from gears and connecting rods to sprockets and bearings. It’s also used to 3D print parts.

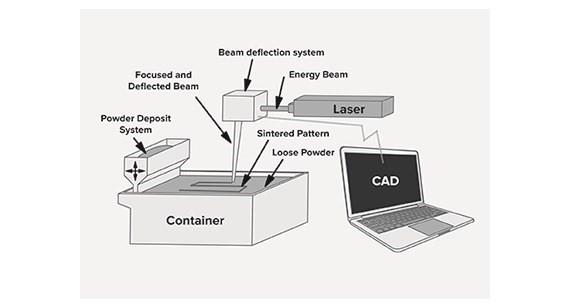

Selective laser sintering (SLS) is a close cousin to direct metal laser sintering (DMLS), but builds parts made of plastic rather than metal. SLS uses a computer-controlled CO2 laser versus an ND: YAG fibre laser for DMLS, but both “draw” slices of a CAD model in a bed of material, fusing micron-sized particles of material one layer at a time.

SLS needs none of the support structures typical with DMLS, however, and unlike stereolithography (SL)—the third laser-based additive manufacturing (AM) process available at Protolabs—SLS creates fully functional parts using engineering-grade nylon, and is essentially the only AM technology able to create living hinges and snap-fit assemblies. (These features can be produced with SL, however, they will be much more fragile and not have the life expectancy of those produced with SLS). This makes it an excellent way to prototype injection-moulded products, and can even be used as a low-volume alternative to moulding in some cases.

Rooted in Nylon

As with any additive process, it’s important to understand the many design considerations applicable to SLS. One of these is the material. Despite their wide-ranging uses, all SLS parts are currently limited to nylon materials—the same thermoplastics used in fasteners, flak jackets, frying pans, and thousands of other everyday items. Protolabs offers four grades of these versatile polymers:

- PA 2200: Similar to unfilled Nylon 12, PA 2200 is both stiff and tough, and is used extensively in air ducts, sporting goods, and similar products. It presents a clean, white finish, but with a slightly rougher surface texture than other nylons. It offers high impact and temperature resistance, is very durable and remains stable under a range of environmental conditions. Nylon 12 also has a low coefficient of friction, making it suitable for many types of gears and bearings.

- PA 850 Black: Similar to an unfilled Nylon 11, this tough bioplastic is an excellent choice for parts requiring a living hinge—the lid on a pill container, for example—and offers one of the highest elongation break thresholds in the nylon family. It’s black in colour, produces a smooth surface finish and good part detail, and due to its superb chemical resistance and low water absorption, is ideal for products such as fuel lines, catheters, tennis shoes, and electrical connectors.

Managing the Build

These four types of nylon materials cover many different applications. Despite this, roughly 95 percent of the SLS material consumed at Protolabs is PA 850 (Nylon 11) or PA 650 (Nylon 12), although the mineral- and glass-filled variants are gaining momentum. There’s far more to effective part design than material selection, however, and controlling the in-build curl and post-build warping common with AM is paramount to good part quality.

Much of this control falls to Protolabs. To keep parts straight and true, our technicians will often tip parts slightly in the build chamber. If you’re designing a case for a handheld video game, for example, a compound incline of 10 to 15 degrees in the X and Y axes during the build is probably all that’s needed to keep the walls square and the box lid fitting smoothly. It’s important to point out that some “stair stepping” may occur as a result of this technique, so it’s important to identify cosmetic surfaces when submitting your design to Protolabs for quoting and analysis.

For especially challenging parts, ribs can be used to strengthen large, flat surfaces—if your handheld game design requires a thin lid, a honeycomb or checkerboard pattern on the inside surface will not only strengthen the lid, but also reduce material cost and potential warping.

It’s Never Too Early to Improve Moldability

Many of the rules applied in injection moulding also apply to SLS, making it a solid choice for parts that will eventually be moulded. The use of hole bosses and support struts, and avoiding thick cross-sections are good practices for either manufacturing process. Additional design considerations include:

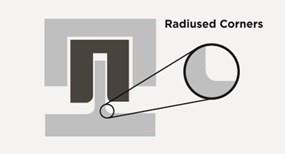

- adding corner radii where walls meet to reduce stress

- uniform wall thickness—between 1.5mm and 3.8mm is recommended to reduce in-build curl and potential for warping

- integrating ribs to reduce warping

Where injection-moulded parts can contain overmoulded metal bushings or threaded inserts, SLS parts achieve comparable functionality via heat-stake inserts—in our handheld game example, threaded inserts can be heat-staked as a secondary process at each corner of the housing for strong assembly purposes.

Look and Feel

The surface finish produced by SLS is a bit rougher than other AM technologies—anywhere from 100-250 RMS—but it still works reasonably well for most functional prototypes. Protolabs also bead blasts the majority of customers’ parts to remove loose powder and create a smooth matte finish. Very fine text is another consideration—since the minimum feature size with SLS is 1mm, very small fonts tend to get jammed with powder, making letters and numbers less legible. Moving to inset text provides better results, but is still limited to features no smaller than approximately 0.5mm. Lastly, SLS is slightly less accurate than competing laser sintering processes—where DMLS has expected tolerances of ±0.01mm plus an additional 0.001 mm/mm on metal parts, ±0.25mm plus ±0.0015mm is typically achievable with SLS. On well-designed parts.

The upside here is that SLS has a build frame of 700mm by 380mm by 580mm, far larger than its metal-making sidekick. And because there are no support structures involved, the entire powder bed can be utilized, making it easy to nest multiple parts into a single build. This makes SLS a solid alternative to machined plastic, a logical stepping-stone to injection moulding, and an excellent way to produce functional nylon parts in higher volumes than is usually associated with AM.

Click here to read more design tips on creating plastic and metal parts for 3D printing, CNC machining, and injection moulding processes.