Read design tip now

Manufacturing prototypes and production parts fast and cost-efficiently is often a balancing act of on-demand CNC machining capabilities and an optimised part designed for those capabilities. As such, there are a handful of important considerations when designing parts for Protolabs’ milling and turning processes that can accelerate production time while reducing costs.

To fully optimise your design for machining, you should look at:

- Hole depths and diameters

- Size and types of thread

- Text on parts

- Wall heights and feature widths

- Live-tool lathes

- Multi-axis milling

1. The 'Hole' Truth

Anyone who has spent more than five minutes in a machine shop knows what a drill bit looks like and what it does. For the most part, however, holes at Protolabs are interpolated with an end mill rather than drilled. This machining method provides great flexibility in terms of the hole sizes available with a given tool, and offers better surface finish than that obtainable with a drill. It also allows us to use the same tool for machining slots and pockets, reducing the cycle time and part cost. The only downside is that holes more than six diameters deep become a challenge due to an end mill’s limited length, and may require machining from both sides of the part.

2. Threading Right

Drilling and thread-making go hand in hand. Many shops use “taps” to cut internal threads. Taps look like a screw with teeth, and are “threaded” into a previously drilled hole. We take a more modern approach to thread making, using a tool called a thread mill to interpolate the thread profile. This creates an accurate thread, and a single milling tool can be used to cut any thread size that shares that pitch (the number of threads per inch), saving production and setup time. Because of this, UNC and UNF threads from #2 up to 1/2 in., and metric threads from M2 to M12 are possible, all within a single toolset. (Learn more about threading here.)

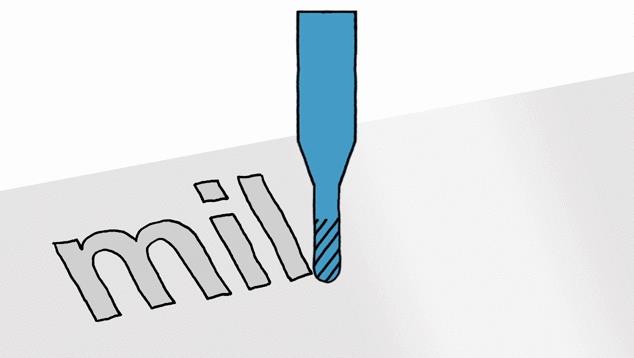

3. Be Careful Texting

Do you need a part number, description, or logo milled on your parts? The toolsets at Protolabs are capable of machining most any text required, provided the spacing between individual characters and the stroke used to “write” them measures at least 0.5mm. Also, text should be recessed rather than raised, and it is suggested 20-point or larger fonts such as Arial, Verdana, or similar Sans-Serif fonts be used.

4. Tall Walls and Tiny Features

All of our toolsets contain carbide cutting tools. This super rigid material offers maximum tool life and productivity with minimal deflection. Yet even the strongest tools deflect, as do the metals and especially plastics being machined. Because of this, wall heights and feature sizes are very dependent on the individual part geometry as well as the toolset being used. For instance, the minimum feature thickness at Protolabs is 0.5mm and the maximum feature depth is 51mm, but that doesn’t mean you can design a ribbed heatsink using those dimensions.

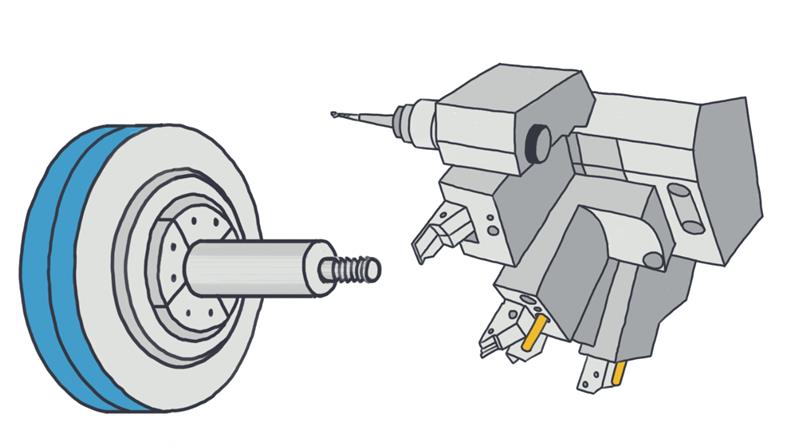

5.Live Tool Lathes

Aside from extensive milling capabilities, we offer live-tool CNC turning. The toolsets used on these machines are similar to the ones on our machining centres, except we do not turn plastic parts at this time. That means off-centre holes, slots, flats, and other features can be machined parallel or perpendicular (axial or radial) to the “long” axis of the turned workpiece (its Z-axis), and will typically follow the same design rules as those applied to the orthogonal parts made on our machining centres.

The difference here is in the shape of the raw material rather than the toolset itself. Turned parts such as shafts and pistons start out as round stock, while milled parts-manifolds, instrument cases, and valve covers, for example-typically don’t, using square or rectangular blocks instead. As you’ll read in a moment, we've overcome those limitations also.

6. 5-Axis Machining

Two distinct “flavours” of milling exist at Protolabs. With 3-axis machining, the workpiece is gripped from the bottom of the raw material blank while all of the part features are cut from the top. Each side of the workpiece thus requires a separate setup, and with parts larger than 254mm by 178mm, only the top and bottom can be machined: no side setups! Indexed milling, though, allows up to five sides of the workpiece to be machined in a single setup. With 5-axis milling, the part can be indexed to 90 degrees in any given angle (and at multiple, or compound, angles), allowing for complex, non-orthogonal positioning.

The toolsets used in either case are identical. What’s different is the raw material. As with our lathes, rod stock is used for index-milled parts, which presents some interesting mathematical discussions about the size, geometry, and positioning of the workpiece within that raw material volume (it’s that whole Pythagorean theorem thing you learned in high school). For some examples of this, you can look closely at the accompanying diagrams, or just upload your CAD model online at protolabs.co.uk for a real-time example.

For personalised support, please contact our Application Engineers with your questions at +44 (0)1952 683047 or email: customerservice@protolabs.co.uk.