When choosing a production partner, thankfully, the decision can be narrowed down. Undoubtedly, you will require specific processes, materials, expertise, etc., which not everyone can offer. Once you have narrowed down this list of capabilities, the next question is often, who can give me the best value? Who can deliver my part the quickest? But it is worth looking into your manufacturing partner’s process.

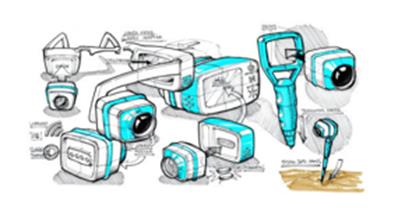

Back to the drawing board

Pick a partner who allows you to upload your CAD file and amend it as often as you want! Ideally, for free! At Protolabs, our automated design for manufacturability software has no cost. You can amend and upload as many times as you like. If you are keen to use us and can’t quite get your part to meet our capability requirements, why not book a meeting with one of our engineers? Our complimentary consultant design service offers up Protolabs engineering expertise. Whilst we are not a design consultancy, our engineers are experts in the services we provide here, and they will work with you to help you achieve your aim of producing a manufacturable part.

Rapid Prototyping

Pick a partner who can produce your prototypes quickly! When you’re designing, prototyping is key. Rather than waiting weeks for prototypes to come back so you can test them. Why not work with Protolabs, who can provide parts as fast as a day? While speed depends on complexity and size, we are the quickest in manufacturing, so upload your CAD and find out how soon you could be holding your first test part.

Aluminium Tooling?

You may read that heading and think; I do not want aluminium tooling – we would ask you why. At Protolabs, we often use aluminium tooling due to its speed and cost efficiency. If you eventually move to production with us and are concerned that your tool won’t last, don’t worry. At Protolabs, when you move to our on-demand production service, your tool comes with a lifetime guarantee! That means if that aluminium tool you are worried about needs replacing, we will do it at no extra cost.

No minimum order quantities (MoQs)

Chances are, when you are starting out, you will be keen to find a supplier who doesn’t have a minimum order quantity to make the process more expensive and less efficient. At Protolabs, we have no MoQs, so order away as little as 1 part and as many as 25,000+.

On-Demand Production

Find someone who can support you with scaling up. Whilst a small prototyping house might seem like the perfect solution at the start, if you do decide to move on to production, you then have to start again with someone who can offer production capabilities. At Protolabs, we offer both!

So you’ve prototyped with us, and now you want to start considering production runs? We are not just a prototyping service (as our name might imply) our extensive on-demand manufacturing service is here to support you with your low-volume production needs. We offer bridge tooling to help support you with the transition. We also pride ourselves on the size and scale of our shopfloors and on our infinite capacity. How can we say infinite capacity? Easy, we scale up as the business need requires. Not convinced? Feel free to come and book a tour with us and see what we’re about.

Quality is key

Select a supplier who doesn’t cut corners. You want speed, you want low cost, but you also don’t want to cut down on quality. Here at Protolabs, we adhere to ISO 9001 standards in regard to the quality of our production parts, but we also adhere to other quality standards. Some are process-specific, for example, we offer ISO 13485 in our Direct Metal Laser Sintering service, which is important for parts required in the medical industry.

We also offer various inspection reports, measurement reports, manufacturing analyses, etc. to read more on these, please visit our process pages.

Finally, find a partner with global reach. Many manufacturing partners have a global presence, which can help design firms access international markets and customers. Here at Protolabs, we have production facilities across the globe, but it doesn’t stop there. Have a part that doesn’t fit our capabilities? We also have our Digital Network and kind find the capabilities you require at one of our network facilities across the globe.

Most design firms won’t have onsite production facilities and will require a partner to support this provision, bridging the gap between the design concept and the actual product. These partnerships should offer manufacturing expertise, cost-effectiveness, time efficiency, quality assurance, scalability, access to technology and risk mitigation.

A partnership with Protolabs can help bring your ideas to life quickly and efficiently whilst maintaining high-quality standards. Check out our dedicated Design Firms industry page to give you the insight you need to choose Protolabs as your manufacturing partner.