How to Use Multi Jet Fusion for Functional 3D-Printed Parts

Technology giant HP has developed and launched Multi Jet Fusion (MJF), an industrial-grade 3D printing technology that quickly and accurately produces functional prototypes and end-use parts for a variety of applications. Protolabs served as one of several test sites for this additive manufacturing process because of its experience in industrial 3D printing, and recently added HP Jet Fusion 3D 4200 printers to its suite of manufacturing tools. Here are several considerations to keep in mind when designing for MJF.

SLS Similarities

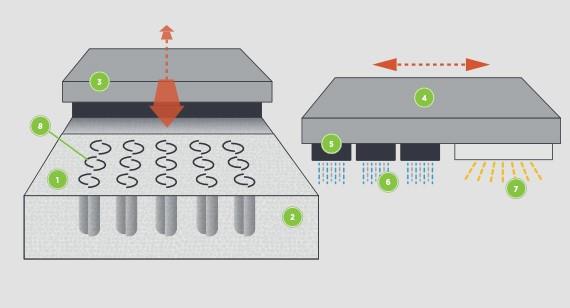

If you’re familiar with selective laser sintering (SLS) design principles, you’re already close to being an MJF master. Both are powder-bed 3D printing technologies, using a heated chamber, the entirety of which can be used for making parts—there’s no need for supports as there is with other 3D printing processes. Where SLS uses a laser to fuse individual powder layers, MJF uses an infrared heating element together with proprietary fusing and detailing agents.

Regardless of the actual manufacturing process, MJF produces fine features and more consistent isotropic material properties, and is suitable for complex, low-volume quantities of parts like brackets and clips, mechanical assemblies, component housings, and durable but accurate jigs and fixtures.

How MJF is different

- Resolution: MJF prints in layers 80 microns thick, and boasts a minimum feature size of 0.020 in. (0.5mm). This is finer than the 0.75mm produced with SLS, but MJF-produced part details are a bit more variable at this size range, with expected tolerances of +/-0.25m +/- 0.002mm/mm vs. +/-0.2mm +/- 0.002mm/mm for SLS. Be aware that these tolerances will vary depending on part size and geometry, so pay particular attention on designs that require tight clearance such as housings or multiple mating parts in an assembly.

- Part Size: At 284mm by 380mm by 380mm, MJF’s maximum build envelope is a bit smaller than the 676mm by 367mm by 564mm size available with SLS. This means the maximum dimensions of any individual MJF-generated part cannot exceed 264mm by 343mm by 348mm, although this is plenty big for many 3D-printed parts.

- Materials: Because MJF currently prints only unfilled Nylon 12 (PA12) and UltrasintTM TPU-01, SLS has a slight edge in terms of available materials and colours (for now). However, Nylon 12 provides a breadth of mechanical or thermal properties that are often required of functional parts and in end-use applications. If cosmetics are important we recommend a light bead blast for parts made with either MJF or SLS.

At a glance: MJF vs SLS

MULTI JET FUSION | SELECTIVE LASER SINTERING |

Finer minimum feature resolution | Better small feature accuracy (small feature tolerances) |

New process with accelerated build time | More consistent surface colour without secondary operations |

More consistent isotropic mechanical properties in the Z build direction when compared to other additive manufacturing processes | Established process with longer build time |

Improved surface roughness | Broader selection of materials, including filled and specialty materials |

| Larger available build envelope |

Stronger parts, faster process

Multi Jet Fusion selectively applies fusing and detailing agents across a bed of nylon powder, which are fused in thousands of layers by heating elements into solid functional components.

It’s also important to consider areas in which MJF excels. For starters, MJF builds strong parts, with tensile strength at the upper end (XY and Z, 48 MPa) of what’s possible with SLS. More important, MJF produces more consistent mechanical properties in each direction of the part geometry—far more so than other powder-based printers—a factor that’s especially desirable with multi-faceted, complex designs where strength and reliability is required everywhere throughout the part. So even though MJF is slightly less accurate than SLS on small part features, those features will be more robust.

MJF is also much faster than competing processes. Rather than tracing each individual detail in a build layer, MJF scans the entire surface on each pass at a consistent rate, regardless of how many parts are in that layer (similar to how a laser printer prints each page in a document). Depending on what’s being 3D printed, this provides build speeds several times that of competing technologies, even with larger quantities. To understand what impact this might have on your project, simply upload the CAD file and compare the quoted lead time and price to Protolabs’ other 3D printing or machining services.

Design Elements to Consider

Multi Jet Fusion parts are 3D printed in a natural gray Nylon 12 material, however, parts can be easily dyed jet black (as pictured) for improved cosmetic appearance.

Many of the design principles applied to SLS and even injection-moluded parts are just as relevant to MJF:

Thin-walled or large, flat surfaces should be reinforced with ribs or gussets, and holes surrounded with raised bosses wherever possible. Raised text and cosmetic part features smaller than 0.5mm might not survive secondary post-processing. Check the design for manufacturability analysis that accompanies your part quote for details. Wall thicknesses from 2.5 to 3.8 mm are ideal. Get much above or below this and part tolerances may be affected. MJF does a great job with assemblies, living hinges, snap fits, and pin hinges. As with any 3D printing process, MJF produces some stair-stepping on oblique angles. Cosmetic surfaces should be clearly identified on the part drawing or digitally in the product manufacturing information (PMI), so Protolabs can attempt to orient the parts in the build chamber accordingly. Protolabs can install heat-stake threaded inserts and metal bushings in MJF parts. And in addition to dying parts black, application of primer paint is also offered.Sound familiar? As mentioned at the start of this design tip, MJF is similar in many ways to other additive manufacturing technologies, offering predictable part quality and possessing design rules that are well understood. What’s different is its unique ability to make accurate parts with isotropic mechanical properties, and in many cases do so more quickly than other 3D printing methods. Together, these attributes have the potential to make MJF an additive game-changer.

And although MJF is limited to PA12 nylon at this time, Protolabs and HP are regularly investigating additional materials, including flame-retardant and glass-filled nylon, elastomers, and multiple colours in a single build. This may be a good time to consider what role MJF can play in your current and future part development projects.

As always, feel free to contact one of our applications engineers with any questions at +44 (0) 1952 683047or customerservice@protolabs.co.uk