This move also demands an increase in computation to solve the accompanying perceptual, planning, and control tasks ‘robots in the wild’ require. Advances in software, particularly artificial intelligence (AI) and machine learning, go some way to deliver the smart robots of the future, but computing platforms will also take a significant role in the future of solving complex perceptual and control tasks.

In the first half of this chapter, we give an overview of the core hardware requirements for most robotics projects. In the second half we look at the rise of embedded systems that enable cutting-edge robotics.

Robotics hardware overview

Sensors

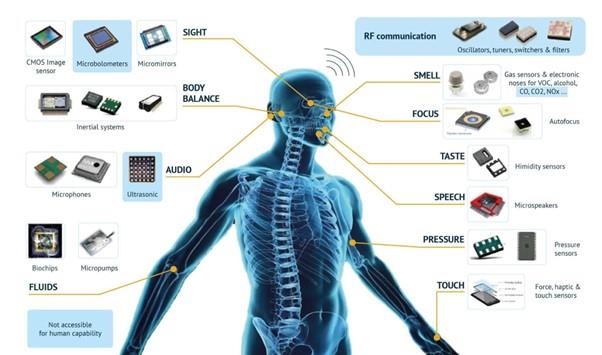

Sensors are the method by which the robot receives input from the world around it, similar to the human senses of sight, hearing, balance, touch, and smell. Common types of robot sensors are:

- Cameras for a visual of the environment

- Microphones to pick up sound

- Force sensors to detect weight and resistance

- Proximity sensors that pick out objects in an environment

- Gyroscopes that identify robot orientation

- Environmental sensors to measure humidity, temperature, gases, pollutants, and other factors

Sensors are passive, meaning that they do not give the robot any type of direction. Instead, the information from the robot’s sensors is typically sent to a central processing unit (CPU), where the input is transformed into action.

One of the biggest trends in robotics sensors is the increasing use of ultrasonic sensors. An ultrasonic sensor measures the distance of a target object by emitting ultrasonic sound waves, and converts the reflected sound into an electrical signal.

Various robotic sensors compared to human senses and capabilities. Image credit: Yantra Parignan

Central processing unit

The CPU is the hardware and software interface between the robot sensors and the control system. The CPU parses commands for the robot to execute and routes them to specific components of the robot. In automated robots, it processes the information received from the input sensors, interprets the information, performs calculations, and may apply machine learning algorithms. In that sense, the CPU functions as the major component of the robot’s brain.

With the advent of artificial intelligence and edge computing, newer SBCs have AI-friendly designs to boost efficiency and drive greater applications. Edge computing allows data processing and analytics to take place at the network’s edge, providing rapid real-time insights and allowing SBCs to be used in IoT-based systems with greater ease and adaptability. One of the most significant benefits SBCs offer is flexibility in platform configuration. The system can be designed with minimum requirements and can then be scaled according to the application. Purpose-built PC systems do not provide such agility.

Control system

The robot control system sends the commands that govern the robot’s actions, similar to the human nervous system, which sends the signals that direct the human body to move. The robot control system depends on the robot’s level of autonomy. Hardware for the robot control system can take many forms, depending on the environment, tasks to perform, and manufacturing capabilities. For example:

- A manual or semi-autonomous robot may be controlled using various types of hardware, such as a personal computer, a purpose-built hand controller, headset, foot pedals, a microphone for voice commands, or even a textile-based controller, such as a VR-like bodysuit.

- An autonomous robot may be controlled entirely by the onboard CPU, or it may be controlled by software on an external server.

Motors and actuators

Motors and actuators are the mechanisms for robot mobility, similar to the human muscular and cardiovascular systems, which provide the means for human movement. Without motors and actuators, the robot cannot perform tasks in the physical world.

Advances in motor technology enables smaller casings, which are often injection moulded, so that motors are more agile and have an increased range of applications. Recent advances in motor design include newer permanent magnets that distribute more power with smaller motors. Higher-resolution encoders improve accuracy, and motor tuning can also be improved to help with accuracy and cycle time. This creates opportunity for higher-precision robotics applications, and it improves repeatability and the throughput of the robot and automation. Smaller motors with better torque-to-weight ratios achieve higher peak speeds for a short time, as well as faster acceleration and deceleration times. Smaller motors also reduce robot mass, which in turn permits more rigidity and reduces vibration.

End effectors

End effectors (sometimes called end-of-arm tools or EOAT) are mechanical assemblies positioned at the end of a robot arm that allow the robot to manipulate objects in the physical environment. End effectors essentially act as the robot’s hands, although their function varies from that of human hands.

Some robots have a combination of gripper and tool-specific end effectors. For example, a robot built to weld pipes may have a welding torch at one arm and a gripper to hold the pipe in place at another.

With interchangeable end effector attachment systems, the operator can choose the best tool for a task, whether it is a specialised power tool, or a more generalised gripper-type attachment. Some grippers can hold and operate tools, though they may offer less precise control for a human operator than tool-specific end effectors.

The field of soft robotics extends the versatility of end effectors by replacing rigid components with softer and more flexible end effectors. Soft robotics mimics biological qualities, which may improve a robot’s ability to manipulate fragile or pliable objects. Minimising rigid surfaces on the robot may also reduce safety hazards for robot operators.

Connectors

Connectors are used in robotics to relay commands and power throughout the robot. Motors, actuators, sensors, and end effectors require both data bus and electrical circuits to operate. Today, many types of connectors serve the purposes of robotics. Commercial connectors are available in housings that can withstand harsh environments and are flexible enough to handle the robot’s movement. Connectors can inform robot design and assembly at end effectors and robotic joints, and can affect the speed of data transfer.

Powering the robot

The power supply is a major manufacturing challenge, particularly for mobile robots. Stationary robots may connect directly to an industrial power source, while mobile robots are usually powered with rechargeable lithium-ion batteries. Batteries may require custom design and manufacturing based on robot Wattage requirements, mobility, weight restrictions, charging source, and environmental factors.

The power source for charging the robot battery is another important consideration. It may be necessary to design a specialised battery charger that accounts for the battery’s power requirements, power source limitations, and environmental factors. The charger may be installed directly on the robot itself or the charger may be designed as standalone equipment. Another design consideration for battery-operated robots is battery hot-swapping during robot operation. A robot with hot-swapping capabilities is powered with multiple batteries. When one battery is discharged, it can be replaced while the robot is in operation. The discharged battery is then recharged for future use.

Summary

Robots have many applications that extend human capabilities, and robot hardware requirements vary depending on the tasks that a robot is built to perform. Common parts of a robot are sensors, the CPU, motors, actuators, end effectors, and connectors. All of these components pose hardware considerations individually and as part of a system.

Outside of the robot’s working parts, there are other factors that raise hardware challenges for robot manufacturers. Resource shortages can result in design changes and manufacturing delays, while environmental conditions limit the materials and components used on the robot, and may require software-based solutions.

Recent innovations in robotics technology include increased computational power, advanced software solutions, as well as the development of biomimicry, such as software based on insect brains, smart skin, neuromorphic computing and other emerging technology. These innovations extend the capabilities of robots and advance the field of robotics hardware.

--

References

- Gabriel Aguiar Nour, State of the Art Robotics, Ubuntu Blog, May and June 2022 edition

- Sven Parusel,Sami Haddadin, Alin Albu-Schaffer, Modular state-based behaviourcontrol for safe human-robot interaction: A lightweight control architecture for a lightweight robot, IEEE International Conference on Robotics and Automation, 2011

- Mathanraj Sharma, Introduction to Robotic Control Systems, Medium Newsletter, Sept 2020

- Ravi Teja, Blog on Raspberry Pi vs Arduino, www.electronicshub.org, April 2021

- Mats Tage Axelsson, Top 5 Advanced Robotics Kits, www.linuxhint.com, September 2022

- Techopedia contributor, Actuator, www.techopedia.com, Jan 2022

- Tiffany yeung, What Is Edge AI and How Does It Work?, https://blogs.nvidia.com/blog/2022/02/17/what-is-edge-ai/, Feb 2022

- NT Desk, The state has the potential to grow as an electronic manufacturing centre, www.navhindtimes.in, Oct 2019

- Dr Matthew Dyson, Printed Electronics: Emerging Applications Accelerate Towards Adoption,IDTechEx, Nov 2021

- Advanced network professionals blog, www.getanp.com/blog/35/hardware-your-business-needs-to-succeed.php, Dec 2019

- Advanced Mobile Group, The Latest Technology and Supply Chain Trends in Robotics for 2022 and Beyond. https://www.advancedmobilegroup.com/blog/the-latest-technology-and-supply-chain-trends-in-robotics-for-2022-and-beyond, Oct 2022.

- Moncourtois, Alyce. Can Insects Provide the "Know-How" for Advanced Artificial Intelligence? AeroVironment, 2019. https://www.avinc.com/resources/av-in-the-news/view/microbrain-case-study

- Yirka, Bob. Biomimetic elastomeric robot skin has tactile sensing abilities. Tech Xplore. June 2022. https://techxplore.com/news/2022-06-biomimetic-elastomeric-robot-skin-tactile.html